GiS mbH

Höllochstraße 1

D - 73252 Lenningen

Tel: +49 (0) 7026 - 606 - 0

Fax: +49 (0) 7026 - 606 - 66

e-mail: rfid@gis-net.de

In sorter systems for textiles

a huge amount of garment pieces are transported on a tracking system and are split into batches by switches. This sorting process is often multi-staged,

the single batch is sorted by items, size, color, etc. itself. These batches correspond to the orders of the customers and are delivered later,

either directly to the customer or to middleman or a department store.

In sorter systems for textiles

a huge amount of garment pieces are transported on a tracking system and are split into batches by switches. This sorting process is often multi-staged,

the single batch is sorted by items, size, color, etc. itself. These batches correspond to the orders of the customers and are delivered later,

either directly to the customer or to middleman or a department store.

Up to now the sorting process, i.e. the identification of the single garment and the correct opening of the exit switches has been controlled with Barcodes.

The problem occurred that the single barcode-reader was too expensive to be used at every single switch. So in the sorting process one single barcode reader

controlled a number of switches. The distance from the reader to the correct switch was controlled by a clock generator, for example the 6th switch had the

distance of 12 cycles. But in time the transport chain became longer and so distances became incorrect and as a result errors in sorting out occurred.

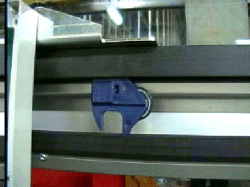

When the new type of RFID reader TS-R60 was developed by GiS, the producer of conveyor technique took the chance to realize a new concept of sorter control,

which is independent from these mechanical changes in the drive. The change over to transponder technique became possible, because the new transponder reader

is considerably cheaper than the barcode reader. So the transponder reader can be lodged at any sorting point and a secure and maintenance-free solution has

been found.

One of the first projects was a sorter

plant for jeans at C&A in Weiterstadt, Germany.

One of the first projects was a sorter

plant for jeans at C&A in Weiterstadt, Germany.

The sorting of the garments has this basic structure:

At each hanger drag a transponder is located, its number is connected with the jeans and the batch in the host computer. At every switch the reader checks

the number and opens the switch if necessary. The garment is sorted out while being transported. Errors in sorting are nearly impossible that way.

Mechanical changes are unimportant, because the garments are recognized at each single switch, irrespective of the cycle.

Additional advantages are the well known characteristics of the RFID-technique: Dirt, which you often have in the textile production, doesn’t cause any

trouble because of the contact less identification. The reader are robust, immune to interfering and maintenance-free. The single readers can be

installed close together without interfering with each other, so very compact projects can be realized.

Even the control system itself is simplified using TS-R60 reader. Up to 128 reader can be joined together in one network, so that one PC can control

a larger installation. The internal intelligence in the reader reduces the higher order control considerably and requires lower wiring efforts.

In our example the single reader triggers the opening of the switches without feedback to the host computer.